The efficiency of the Campo Limpo System is the result of processes and information management. By acknowledging this, inpEV adopts new technologies and new information management processes based on economic feasibility, always focusing on solutions that seek economic self-sufficiency for the System.

The Central Offices Information System (SIC) is a concrete example of this. It supplies the quantities and type of material hauled until the previous day in real time, and assists management and the decision-making process.

In the second half of 2014, the Logistics System module (SisLog) started being implemented, which will be expanded in 2015. Developed in partnership with member companies, SisLog allows to assess and optimize shipping and transportation costs. Besides this, it has been adapted to another logistical characteristic of SCL: the use of around 90% of trucks with up to 13.5 tons of payload. G4-EN30

Technology for farmers

Adopted at 35 central stations in 2014, the Empty Packages Return Scheduling (adEV - Agendamento de Devolução de Embalagens Vazias) offers another return option to farmers for their post-consumption packages, who can schedule their deliveries in the long term using their computers, mobile phones or tables.

Scheduling allows inpEV to predict the amount of empty packages at the central stations and ensures a more efficient logistical operation as well as better use of labor. The goal for 2015 is to expand this service to all central stations.

35 central stations offer electronic scheduling services to return packages

Care with the environment

Before delivering the material at the SCL receiving units, farmers should do the triple wash or wash under pressure of rigid post-consumption crop protection packages (plastic or metallic) according to the procedure described below.

Triple wash

Washable packaging*

1 Completely empty the package content into the sprayer tank.

2 Fill 1/4 of its volume with clean water.

3 Tighten the package cap and shake for 30 seconds.

4 Pour the wash water into the sprayer tank. Repeat washing procedure three times.

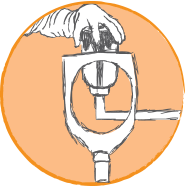

5 Void the plastic or metallic package by making a hole in the bottom.

*Only plastic and metallic packages that are submitted to the washing process at the time the product is used as well as cardboard boxes and lids are recyclable.

Wash under pressure

Washable packagings*

1 Completely empty the package content into the sprayer tank.

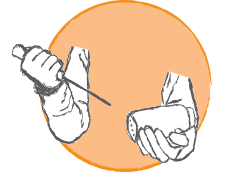

2 Fit the empty package to the proper location on the funnel installed on the sprayer.

3 Actuate the mechanism to release the water blast.

4 Direction the water blast to all internal walls of the package, for 30 seconds.

5 Transfer the wash water to the inside of the sprayer tank.

6 Void the plastic or metallic package by making a hole in the bottom.

*Only plastic and metallic packages that are submitted to the washing process at the time the product is used as well as cardboard boxes and lids are recyclable.

It is the farmer's responsibility to carry out the wash at the time the product solution is prepared